I had to put two warps on two of my looms to get them looking better for the review.

My Big Macomber will always be my main loom. I love weaving on it. I hope I will be able to for a long time.

|

| Shawl fabric with handspun accents. |

This loom did about 6 warps this year for a total of about 43 yards.

My Baby Wolf is the second loom. I love this loom and have used it lots. This loom lives in my bedroom, so I can thread at night, but not weave. The weaving wakes my DH.

|

| A warp for pillows |

I have added parts, taken it apart for cleaning (probably needs that soon) and enjoyed weaving on it. This year it has woven about 8 warps for a total of about 45 yards.

My Baby Mac is the loom I use now for workshops and testing projects. It has spent it's time in my living room, but with the Bergman and my DS moving out, I am now setting up a study in his old room and I want space for this loom in there.

|

| This has a new S&W sampler, but it is going slow. |

This loom has woven about 6 warps and about 15 yards. Most of these warps are shorter because I use it for tests and classes.

My Dorothy is a loom I acquired by chance. When I bought the Big Mac, at the last minute the owner threw in the Dorothy. I want to add some more shafts to her to be able to test multi-shaft projects.

|

| Folded Dorothy with the workshop warp. |

I only use it when I need it, so this year I only put on 1 warp of 2 yards for a workshop.

The Bergman is a loom that has shown no change in the past year...why have I not worked on this loom?

|

| 12 shaft Bergman |

I feel bad looking at the loom, I need to get some work on it.

This past year I have started teaching at Pioneer Craft House. The studio came with eight floor looms and nine table looms. Most of these looms have been around for many years or were purchased or donated as used looms. Needless to say, the looms need lots of work...most have problems with the brakes and none have been cleaned or oiled in years. The climate is so dry here, that wood really needs to be feed.

The table looms are mostly in great condition, the Schacht table looms are only a few years old and are great for my beginning students.

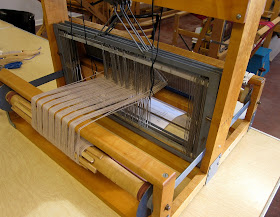

|

One of the eight Schacht table looms.

|

The first loom I worked on was the small folding HD loom. I sanded and oiled and waxed the wood and replaced the leather shaft cords. Here it is with the test loom. It is working great.

|

| HD with a test scarf warp. |

The second loom I worked on is the first Hammett. I cleaned the wood, oiled and waxed it. I also put on new apron and apron strings on the back so that we could use this loom for sectional warping. We also have an AVL Warping Wheel and with this loom, I reassembled the wheel and put on the warp. I still am having problems with the shafts, I don't know as much about counter-balanced looms as I thought. They take a lot of futzing around.

|

| Hammett with the towel test warp. |

The most recent loom I have been working on is the folding Gilmore. They don't make these looms any more, but I have been emailing the company and they have helped me with the repairs to get this loom working. It has had a very tough life. The cloth beam had a piece gouged out at the end, dowels were missing from the lamn frame, and there is a lot of water damage. I cleaned and oiled the loom, I replaced the dowels and now I am waiting for the parts delivery from Gilmore with the bumper pads for the shafts, treadle cords and apron straps. I think it will be a good loom, I hope to put a lace sampler test warp on for my S&W class to weave.

|

| Folding Gilmore waiting for last parts. |

I have a student who wants to weave on the Macomber, so she is willing to do the cleaning and repair on that one. I bought new string from Macomber to replace the apron warp strings that were cut off and I have taken several pictures of the brake system on my loom so that we can get the brake working. The previous teacher had purchased the bolts and such, so we should have all the parts for the brake.

|

| She has already started with the cleaning. |

The second Hammett is next on my list. The Pioneer Craft House was known for rag rug weaving and I am debating putting a long rug warp on a loom for people to rent for weaving. I am not sure yet if there is demand, but this loom would be a good one. I need to clean and oil it and I have ordered new heddles (I hate working with bent heddles that are out of order).

|

| Hammett ready to start cleaning. |

The big HD loom had a warp on it and after replacing the treadle rod, it is weaving. We have used it for lace samples in the overshot class, but it really needs a good cleaning and oiling. I would like to add some more treadle tie-ups so that we don't have to move any when we change tie-ups.

|

| HD waiting for cleaning and oiling. |

There is a second Gilmore. This one is the model they still make, the compact. This loom has a warp on it that a student is working on and the loom is in pretty good shape. It of course needs cleaning and oiling, and I might add pegs to get the sectional beam back. It would be nice to warp without paper! The bumpers on the loom are like wood, so I ordered those parts when I ordered for the folding Gilmore. I'm looking forward to seeing this loom clean and oiled, I learned to weave on a Gilmore and I have a soft spot in my heart for them.

|

| S&W runner on the Gilmore. |

The last of the floor looms is the Leclerc. This loom is only four shafts, but it has a 60" weaving width. This would be great to weave some blankets on. I think there are weavers that would like to rent time on this loom for making large projects. Unfortunately, the brake is put on wrong. I think the previous owner gerry-rigged it to work with what she was weaving. I will need to order parts and even a brake pedal to get this working. The sectional beam was put on strange also. It was not across the full width of the beam and I want to be able to weave the full 60 inches.

|

| Corner of the Leclerc loom. |

So, my goal for looms is to get at least one PCH loom a month, cleaned and weaving with no problems. For each loom I get done there I need to clean and oil a section of the Bergman. By the end of the year, I want my Bergman warped and working and I want nine looms at PCH being used by weavers and producing fabric.

Wow, I have lots to do...But I love making looms work correctly. I want my students to have a great experience working on the looms we have.