On January 8th I reported with great enthusiasm on my Facebook page that I had wound four warps. I really thought I was on a roll. I wanted to have all my looms warped up to start the new year.

The Big Mac had just been emptied after weaving my picnic napkins for the guild show.

|

| Here's how they looked in the show. |

I was in such a hurry to get them hemmed, and I was able to get them in the show, so I was very happy. These napkins had been on the list of things to do for quite some time.

But there sat the empty loom. I wound a warp of wool rug yarn for some pillows to go on my sofa. I have some core-spun rug weft that I want to use....but that is as far as I got until today.

|

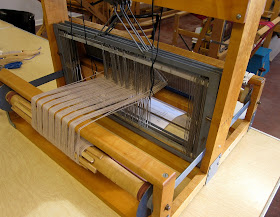

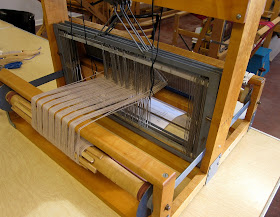

| So here is the warp wound on the beam. |

I have the warp wound around the beam, not threaded yet. The loom is not officially "dressed", but it is not empty...!

My second empty loom is the Baby Wolf. I had been working on the scarf that I designed while I was in Europe. This is the Pont du Gard Lichen scarf. I loved the lichen colors and ordered the yarn. I finished weaving two scarves and took them off, twisted the fringes and entered the best one in the guild show. Again, I was so excited to get it in the show that the loom sat for a few weeks.

|

| Here is how it looks in the show. |

This warp had more ends and actually was on the warp board unfinished for about a week.

|

| The warp sat in the bag for a while until I could get to it. |

This is a shawl based on a design by Sharon Alderman, using a handspun accent yarn and a heather 2/8 wool for the ground.

Again the loom is not dressed completely yet, but at least the warp is wound on the beam.

|

Ready to put the lease sticks in and thread the heddles.

|

The warp I had to get on a loom for the workshop was not a fun one to put on. I was taking a workshop in Theo Moorman technique...so every 3rd warp was polyester quilting thread. The warps were provided for us by the teacher and several of the fine threads did not get caught in the cross. One of my biggest problems was warping the fine gray threads in a room with gray carpet...hard to see, plus the fine threads had a mind of their own and tended to jump out of the heddle that I had threaded them in. In other words, not a fun warp to put on.

|

| Here we are working away. |

I did manage to get the warp done for the class. And spent three days enjoying my weaving friends and trying some things with Moorman that I had not done much of before this workshop. I had done Moorman with threads, but only a little with fabric strips.

|

| Here is my second sampler |

I liked weaving the batik fabric as the ground and adding yarn for the pattern. I designed my initials to weave a couple of panels that I can put into a bag....yeah, when am I going to get that done?

My fourth warp was a demonstration warp for my Summer & Winter weaving class. Because the students work at home, I wanted to have a loom warped in class to show the techniques. I had seen an old 20 inch Structo in the back of my loom closet and it had the wooden beams on the front and back, so I decided to use that. (I don't like to work with the octagonal metal beams that so many Structo's have. Those metal beams were made so that the pre-warped spools could be slipped on the beam.) I had not looked at the loom closely, so the day I pulled it out I had quite an unpleasant surprise. For some reason, back a number of years ago, someone had replaced the top heddle rod on shaft 4 with bailing wire. It had been there so long is was even rusty. I knew I would not be happy weaving on this even for a demo, so I took the shafts out to fix it...then decided the heddles needed to be put on in the correct order...and the wood was very dirty and needed a cleaning...then the poor wood needed some wax/oil/TLC.

This did not turn out to be the quick warp for class.

|

| Cleaned and waxed wood. |

The loom had some damage, but seemed structurally sound. I replaced the rubber bumpers beneath the shafts with felt and then put the newly corrected and repaired shafts back in the loom. The warp was a small one for samples and did not take very long to warp.

|

| You can see the replaced upper rod on shaft four. |

The Structo looked ready to go and it would be that perfect demo loom. That way I did not have to use one of the Schacht table looms and I would be able to use them for the students. I wove the first sample to show the class...well, I actually got about 4 inches done when the third shaft broke!!!

|

| The metal weld broke on the two corners. |

After all that work, I had to transfer the warp to one of the Schacht Table looms, and now I need to find a metal worker that can repair the loom. I am not willing to give up on this loom. I want to continue to use it for a demo loom...once I get it working.

So now you have the first part of the "Saga of the Four Warps". Hopefully, the next episode will have more information about great weaving and less loom repair and problems.

No comments:

Post a Comment